Omega-3 fatty acids are essential for a healthy diet. And thanks to modern processing techniques, high-quality extracts can be consumed quickly and easily in the form of flavour-neutral food supplements. Food and drinks can also be enriched. However, unsaturated fatty acids oxidise quickly, thus degrading the quality of an oil, while lipids are highly susceptible to environmental pollutants. These can get into the raw oils despite careful sourcing, even with organic products. To negate this, Nutriswiss AG has devised gentle processes for the creation and refinement of taste-neutral, omega-3 oils that retain their valuable, health-promoting properties.

Preserving valuable fatty acids

Global demand for marine and plant-based omega-3 products is growing, from dietary supplements, functional foods and beverages to pharmaceuticals, infant formulas, pet food and feed. However, omega-3 oils require a completely different handling process and a higher degree of care than ordinary oils, as their high content of polyunsaturated fatty acids make them unstable and susceptible to oxidation. “Preserving these valuable fatty acids and ensuring that the product remains stable and free from contaminants can be quite challenging,” says Frank Möllering, Head of R&D at the Swiss refinery, Nutriswiss, which specialises in purifying, modifying and refining edible and specialty oils.

Omega-3 alternatives

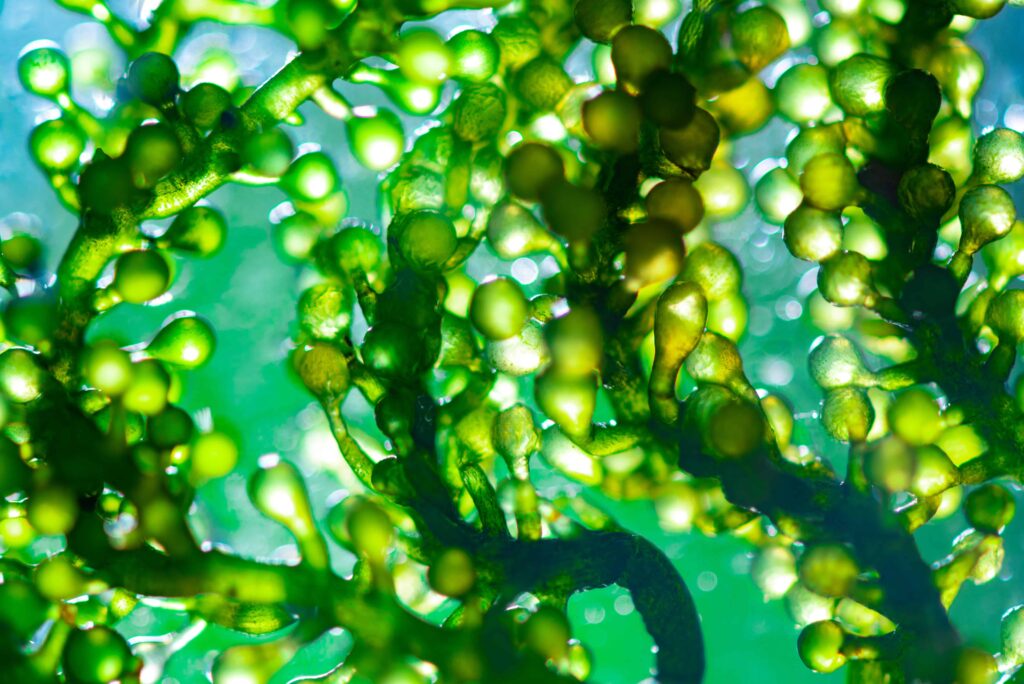

While fish are still the dominant source of omega-3, alternatives such as nuts, seeds and oils are becoming more popular, as are microalgae which can be easily cultivated and reproduce quickly. “Fish get their omega-3 from algae, so why not start directly at the source?” says Möllering: “In addition, algae cultures are more environmentally friendly and protect fish stocks. The market is still in the discovery phase but because we’ve been involved in the purification of algae oil for several years now, we process almost as much algae oil as fish oil.”

Careful treatment and processing

Regardless of their derivation, all omega-3 oils require careful treatment and processing in order to preserve their essential fatty acids, micronutrients and vitamins. Nutriswiss therefore relies on a mild, multi-stage refining technology that minimises the formation of process contaminants. At the same time, free fatty acids, plasticisers, pesticides and mineral oil hydrocarbons are largely removed or greatly reduced. In further treatment steps, the company’s experts optimise the sensory quality where necessary in order to produce an omega-3 oil that is entirely neutral in taste and odour.

However, a high proportion of polyunsaturated fatty acids makes oils unstable and susceptible to oxidation. Unlike vegetable oils, the oxidation reaction causes fish oil to develop a strong odour, darken in colour and rapidly become rancid. For sources with an extremely high omega-3 content, the oxidation potential is correspondingly high. To prevent these quality defects, both the raw material and the refined oil must be kept in a protective atmosphere until processed into the end product.

High demand

At Nutriswiss, a comprehensive “key figure” profile is initially compiled in its analytical laboratory for each oil received, in order to determine how much “damage” has already occurred. Key factors such as the anisidine value, which measures the secondary degradation products of lipid-compound oxidation, provide information about the history of the raw material.

“Using various process steps, we can remove the secondary oxidation products and reduce the anisidine value to below 10. For a fish oil, this is premium quality. The refined oil is also neutral from a sensory point of view and almost the same light-yellow colour as rapeseed oil,” explains Möllering.

Contaminants

Oxidation products are not the only compounds that have to be removed from a crude oil by refining. Owing to their apolar structure, lipids are especially susceptible to environmental contaminants. Oils from plants often accumulate the insecticides, fungicides and herbicides used in traditional cultivation. In addition, mineral oil saturated hydrocarbons (MOSH) and mineral oil aromatic hydrocarbons (MOAH) may have been transferred to the foodstuff during processing and packaging. Marine animals are particularly at risk: even pesticides that have been banned worldwide for decades, such as polychlorinated biphenyls (PCBs), are still present in waters around the world and accumulate in the fatty tissue of organisms.

For manufacturers who, due to their market positioning, require uncontaminated oils of the highest quality and purity for their formulations, Nutriswiss offers access to a self-developed supply chain. As is already the case with oil plants derived from certified contract cultivation, the Swiss also work with selected partners for marine sources who have committed to the highest standards in terms of catch methods, breeding and transport.

Optimal process parameters

As with almost all sensitive natural raw materials, the challenge is in implementing a gentle purification process to preserve the valuable polyunsaturated fatty acids. To remove the contaminants, high temperatures are required, which in turn favours the formation of other contaminants like trans fatty acids and chlorine-fatty acid esters such as 3-MCPD or glycidyl fatty acid esters. For 3-MCPD, in particular, more stringent regulations have been in force in the EU for infant foods since 2021. And tighter restrictions are also being considered for other residues and applications.

Nutriswiss is already prepared for more rigorous legislation. Mild distillation technologies can be used to efficiently remove or significantly reduce impurities in fats and oils. However, it is important that product quality remains stable or is better than that achieved via conventional processes. Nutriswiss has therefore conducted extensive tests to determine the ideal process parameters to meet this goal.

Mild distillation is ideal for sensitive raw materials such as omega-3-rich seed oils, including rapeseed and linseed, as well as algae and other speciality oils. Finding the right blend and quality of oils, especially for infant formula, is a major challenge not only because the fatty acid profile must be optimally balanced, but also because the raw materials must meet the highest quality guidelines and strict specifications for harmful substances. Such oils require customised treatment and a higher degree of care than ordinary oils in order to preserve the omega-3 and omega-6, essential fatty acids as well as tocopherols – better known as vitamin E. As valuable ingredients, tocopherols are welcome not only from a nutritional point of view, but also for product stability and in specific applications.

The mild distillation technology Nutriswiss uses is a gentle, thermal separation process which has already been established in the fish oil sector. Further developed and implemented as one of several purification steps, the plant concept allows contaminants to be removed without generating new ones. It prevents the formation of process contaminants such as 3-MCPD or glycidyl fatty acid esters and, at the same time, removes ortho-phthalates plasticisers and many pesticides. Other pollutants, including MOSH/MOAH, can also be significantly reduced. The gentle process protects micronutrients and can be used to maximise the yield of omega-3 fatty acids.

Tailor-made solutions

Developing custom products is one of the great strengths of the Nutriswiss refinery. Before production starts, each process and method is tested in the laboratory, so that all procedures and methods can be adapted to suit individual applications. Afterwards, scale-up – from small quantities of around 500kg batches to several tons – can be done.

Nutriswiss also offers advice on sourcing and helps with the selection of the highest quality raw material sources. The company’s portfolio currently includes more than 20 different types of oil and is continuing to grow.

Frank Möllering, Head of Research & Development at Nutriswiss (©Nutriswiss)